Sewer cleaning work

Currently, sewerage and drainage systems are subject to regular checks and inspections within the framework of preventive maintenance, carried out by public and private companies specialising in waste disposal.

How can sewer cleaning problems such as:

- removal of silt,

- clearing jams,

- preparing for sewer inspection,

- preparing for repairs

be solved in terms of maximum performance and profitability?

Maintenance tasks for sewers cannot be carried out profitably without the widely used high-pressure cleaning system.

The growing need to reduce costs by providing a more complete service around the cleaning of sewers means that the efficiency of the cleaning process is of vital importance, if a reduction can be achieved at the same time in the use of drinking water.

Our solution:

We offer two models of combined suction and cleaning tanks that include a water treatment system:

The ECONOMIC version and the PROFESSIONAL version.

The superstructures of both models are mounted on a chassis with two, three or four axles and have different features and sizes. They are noted for their robust and uncomplicated technology, easy operation and low maintenance requirements. The water treatment system consists of several cleaning stages and works continuously.

Your benefits

On account of our extensive experience in the development of combined suction and cleaning tanks with water treatment, we are able to offer convincing technical and economic characteristics for professional applications:

- Robust construction and easy maintenance

- Increased cleaning power

- Simple operation of water treatment system

- Water-saving and conservation of drinking-water resources

- High filling capacity of the sludge tank through a separate filtration chamber in the discharge cap

- Very good water quality for high-pressure pumps and the cleaning nozzles

- Choice of either a fixed partition or a discharge piston as an adjustable partition in the cylindrical tank (between the sludge tank and water chamber)

- The use of muddy water close to the surface reduces the workload for the filtration system

- Arrangement for easy handling and cleaning of the filter chamber with a ring filter in the discharge cap

- Sludge tank optionally available with discharge by tipping or forced emptying (with piston)

- Vane vacuum pump with additional outlets for external transfer requirements

- Simple changeover to conventional suction and cleaning operation

- Option to retrofit the water treatment system in suction and cleaning vehicles with conventional technology

- On customer request, the sludge tank can be built with type approval in accordance with GGVSE/ADR regulations

- High profitability through efficient cleaning of sewer systems

- Ecological design incorporates features that help reduce noise

- High-level quality through in-house component design and continuous quality control during the production process

- Wide range of optional equipment for flexible adaptation to special applications

- Rapid continuous run-down of suction hose in inlet wells using a maintenance-free drive

- Technology that has been proven effective in numerous operations, plus a convincing service guarantee, for total security

- Wide range of accessories for multiple applications

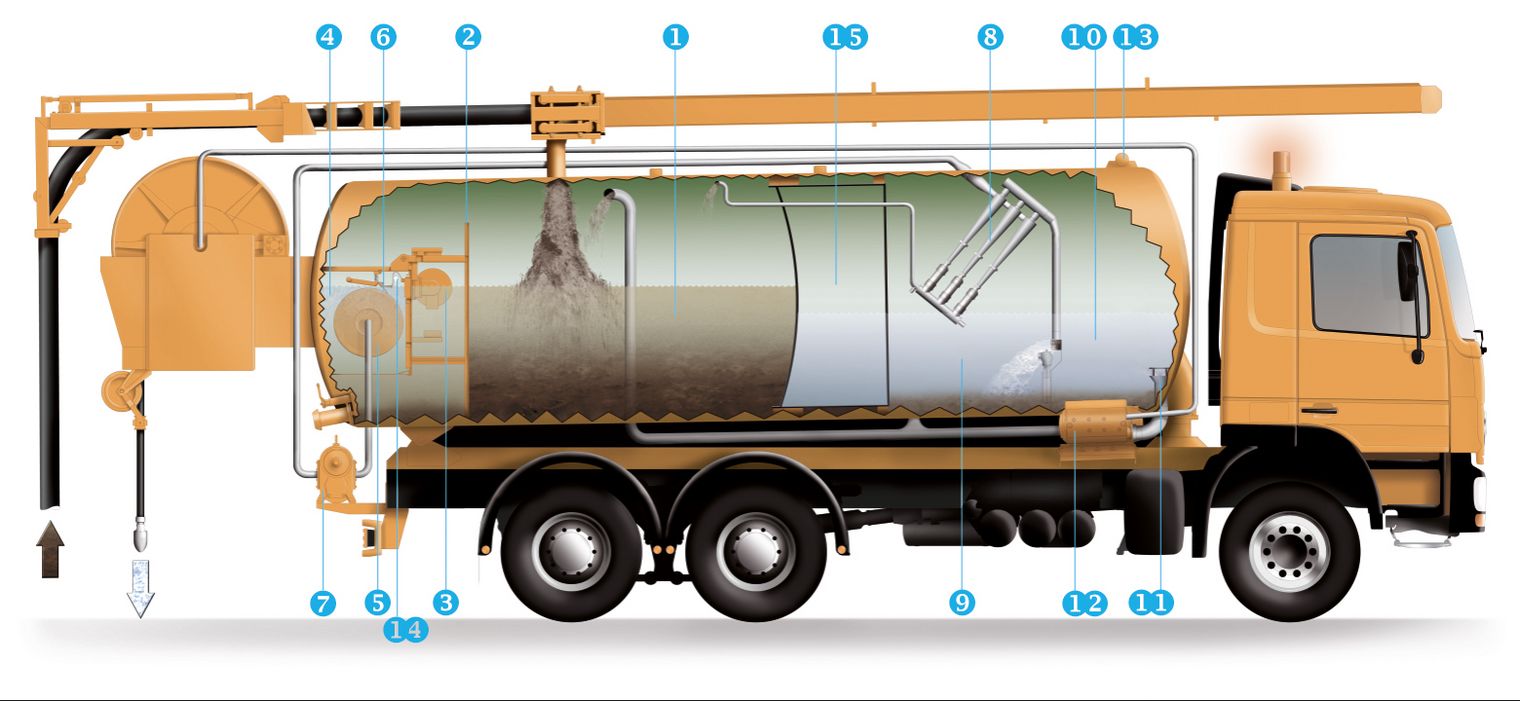

ECONOMIC type - system layout

- Sludge chamber/sludge tank

- Suspended solids separator

- Swivel pipe with float ball

- Filter chamber

- Filter drum

- Scraper

- Vane vacuum pump

- Cyclone battery

- Sedimentation chamber

- Water reservoir chamber

- Suction pipe, flow-optimised

- High-pressure pump

- Filling line for conventional operation

- Spray bar

- Emptying piston / movable partition wall

ECONOMIC system description

Our ECONOMIC tank model mainly consists of a cylindrical tank:

- with a fixed partition between the sludge tank and water chamber, and emptying by tipping, or

- discharge with a piston for forced emptying, and with an adjustable partition that allows the volume to be varied between the sludge tank and water chamber.

The water treatment system comprises several cleaning stages and works continuously:

- Separation of suspended matter and silt through stainless steel filter pivotally mounted in the sludge tank inside the filter chamber.

- Filtration chamber with electro-hydraulically driven ring filter and rotary joint in the discharge cover

- Vane vacuum pump for pumping muddy water from the ring filter to the stainless-steel separator (cyclone battery) that serves to separate abrasive substances (sand)

- Settling basin (laminar water entry via large openings) and sedimentation zones in the water chamber

- Equipment for conventional operation of the superstructure

On request, we are pleased to provide additional information concerning technical details of our CANALMASTER WA ECONOMIC combined suction and cleaning vehicles.