Company

What we do

As a strong partner at your side, we are capable of detailed technical solutions which ensure that your demanding waste disposal activities are entrusted to dependable, purpose-specific waste disposal vehicles. You tell us your requirements so that together we can discuss which technical solution best suits your needs. An analysis of your operational criteria and requirements will be the determining factor for the size and power of the required superstructure and chassis as well as the accessories. We will determine the chassis interfaces in line with the required assembly structure.

Technical concept and construction

Following order placement including the specification of your technical requirements and the appropriate choice of superstructure components, plus the specification of a suitable choice of chassis, our design/development department will undertake a fundamental check of all the technical data in order to produce a detailed solution that corresponds to your requirements.

Following acceptance by our technical department, you will receive the order confirmation along with a construction diagram and weight distribution assessment.

Purchasing and production preparation

Our continuous acquisition process begins following the completion of a parts list. We obtain many of the construction-specific components from long term-suppliers, or they are available from our extensive parts store which contains around 15,000 articles and production parts. A subsequent quality check determines whether the products and purchased parts fulfil the relevant quality standards and requirements.

When your chassis has been delivered, it will undergo an extensive screening by our engineers in order to check and document all the constructional fitting points. The component checks include the type of auxiliary drive, electric and electronic connections, axle variations, choice of tyres, wheelbase, axle constellation, driver cab and engine performance. Should any corrections be necessary, we will contact you immediately.

Tank construction

In our tank construction department, different types of sheet metal are formed to produce various types of tanks. Steel sheet metal or corrosion-resistant stainless-steel pieces can be merged together to become one unit.

Welding is carried out using machines – a job for the welding robot. Controlled by a welding engineer, an electronic welding device ensures that all components are cleanly and precisely welded together. X-ray inspection guarantees the flawless quality of the welding.

Preliminary construction

People cannot be replaced by robots and machines in the process of manufacturing individual waste disposal vehicles. Assembling vehicle superstructures involves a number of jobs that require not only considerable manual skills, but also the relevant professional experience. We meet this challenge in our manufacturing process by forming autonomous assembly groups, each made up of highly qualified employees, who have developed the specialist skills required in mechanics, welding, pneumatics, hydraulics, drive components and electrics/electronics. Our assembly groups construct the vehicle superstructures from start to finish and have a strong feeling of responsibility for the end result.

Approval of preliminary construction

After completion of the preliminary construction as well as the purchase, pre-fabrication and fitting of all components to the chassis, you will be given the opportunity to examine your vehicle before final construction commences. This will give you the opportunity to check the preliminary construction for contract conformity, and at the same time suggest any minor alterations or amendments or specify any accessories you may require. We will produce a protocol of the preliminary construction approval process.

Only when you are satisfied with the approval will we completely dismantle the entire structure.

Spray painting of all steel components

Following the preparation of all structural components in the relevant departments as well as the pressure testing of the tank in our tank construction department, but before final assembly, all surface areas and construction components will be subjected to a shot-blasting process. Subsequently, all the single components will be spray painted with at least three layers of paint in our highly modern paint-shop. This is the only way to ensure stability in value, even under extreme working conditions.

You are assured of high and stable resale values thanks to our widely acknowledged high paintwork quality and the comfort and practical capabilities of our superstructures.

Final assembly

Finally, all the painted main components and parts will be re-assembled. Furthermore, the electric and electronic parts will be completed and the software read into the control system.

The painted and assembled structure is a piece of precision work adapted to your requirements. It stands out through its clear design and attention to detail.

Test lab

Before the vehicle is delivered, it will undergo a final inspection whereby intensive tests and measurements are very precisely carried out and recorded in line with pre-defined test criteria. All functions of the vehicle will undergo thorough tests.

At this stage, various adjustments are made to the vehicle including parameterisation of the chassis engine, calibration of the tachograph, TÜV certification to German standards and all the necessary entries into the logbook as well as an intensive test run of the vehicle, various aspects of fine tuning and a further check of the scope of supply. Furthermore, the guaranteed noise levels are measured and recorded with respect to machine noise level regulations.

Vehicle handover and training

After the intensive vehicle testing, we will give you theoretical and practical training as to the correct operation of the vehicle. Our skilled training staff will simulate a typical working operation. During the vehicle training, we will hand over the operation and service instruction manuals, a spare parts list and a large-scale photograph of your new vehicle.

Your comprehensive induction to your new vehicle is particularly important to us, as we would like to demonstrate the true performance of your new “workhorse”. Our prime objective is to ensure that you are a satisfied customer.

Commercially successful

We are broadly positioned with our diversified product portfolio. Our products are the result of decades of intensive development coupled with a consistent customer focus.

Our products demonstrate their reliability day in, day out in the following segments:

Liquid waste disposal vehicles

Our comprehensive range of components and systems extends from small flushing vehicles for pipe cleaning to complex suction and jetting vehicles with water treatment systems.

Operation, control and regulation systems

User-friendly interfaces ensure efficient vehicle operation and intelligent data communication.

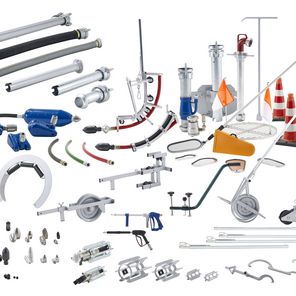

Accessories for liquid waste disposal vehicles

We have the all the accessories for your applications, from flushing nozzle and jetting hose to shaft corner guide roller and the perfect suction hose.

Blocking systems and leak detection systems

Our products are developed according to a system concept and can be combined in a variety of ways. This allows you to put together an individual solution bundle for your specific requirements.